If you own or operate an elevated work platform (EWP) in Brisbane, you know how essential it is to keep your equipment in perfect working order with regular EWP maintenance. An unexpected breakdown can jeopardise safety, delay projects, and result in hefty repair costs.

For Australian EWP operators, you also don’t want to fall on the wrong side of strict workplace health and safety (WHS) regulations. On-site safety isn’t just about ticking boxes – you want to ensure your team, property and clients are as safe as possible, always.

By sticking to a proper maintenance routine, you’ll not only extend the life of your EWP but also keep your costs down and your team safe. Today Altequip is going to walk you through the key components of a comprehensive EWP maintenance plan.

The Importance of EWP Maintenance

EWPs are important machines to a number of industries, but they do carry risk. They’re often subjected to wear and tear from heavy use, harsh environments, and demanding tasks. Without proper care, they can fail at critical moments, putting workers’ lives and your business continuity on the line.

Here’s why regular maintenance matters:

- Safety comes first. Well-maintained EWPs reduce the risk of accidents caused by system failures.

- Compliance with Australian laws and standards. Regular inspections and record-keeping are mandatory requirements under WHS regulations. Failure to comply can lead to fines or penalties.

- Higher efficiency and uptime. Scheduled maintenance minimises downtime and ensures your EWP is always ready to go.

- Cost savings. Preventative maintenance solves small problems before they become expensive repairs.

Best Practice for Maintaining Your EWP

A sound maintenance strategy for your EWP has several moving parts. Here are five practical steps to maintain your EWPs and keep them running smoothly.

1. Regularly Inspect Your EWP for Issues

The safest way to operate an EWP is to identify and fix issues before they escalate. There are four primary types of inspections:

- Pre-operational inspections. These are basic visual checks done at the start of every shift. They include looking for obvious faults like cracks, oil leaks, or low tyre pressure.

- Routine inspections. These are more detailed checks conducted every three months. Lubrication, torque checking, and testing brakes and lights are just some of the items on the checklist.

- Periodic inspections. Completed annually, these inspections cover larger components—scissor, chassis, boom, power system, and hydraulic and electric systems.

- Major inspections. After 10 years of service (and then every five years), you’ll need to complete a major inspection. Dismantling and inspecting critical components (some may require full disassembly and removal of grease and corrosion) to assess and record their serviceability.

2. Stick to Manufacturer Guidelines

The manufacturer knows your EWP better than anyone. Always follow their maintenance schedule and recommendations. If you no longer have it (older or imported machines), you can always get in touch with the team at Altequip for guidance.

Look out for service intervals based on usage hours or operating conditions. For example:

- High-use EWPs may need more frequent servicing.

- Machines operating in harsh environments (e.g., heat, dust, or salt exposure) require extra care to prevent accelerated wear or corrosion.

Skimping on routine maintenance might save you some time and money upfront—but it could cost you a lot more in the long run.

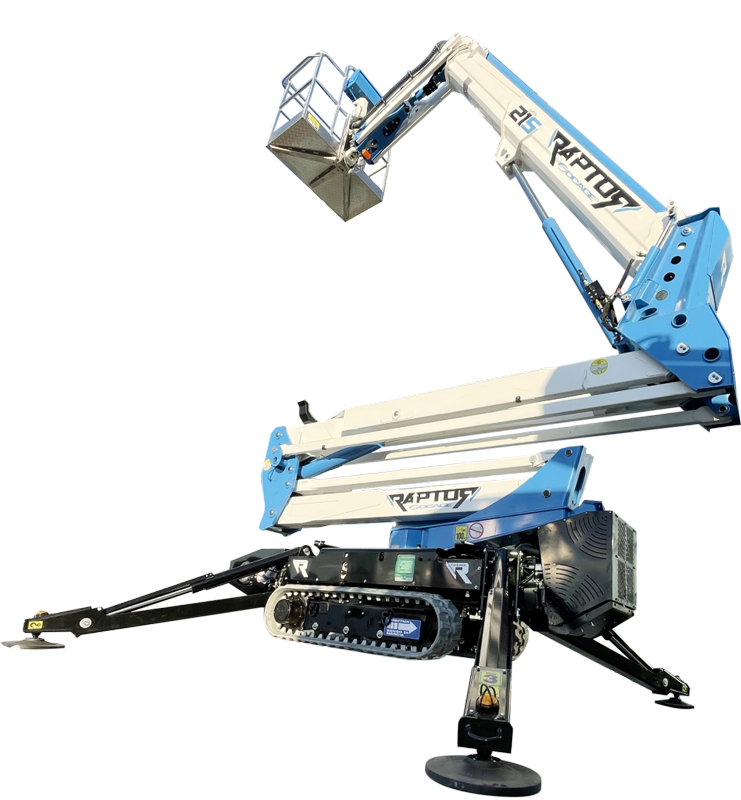

At Altequip, we have direct factory support from Socage in Italy. If you are invested in this premium brand of EWP, you know it’s in safe hands when it comes to us for servicing.

3. Address Safety Issues Immediately

Safety shouldn’t wait. If an inspection identifies any issue—even minor ones involving fasteners, hoses, or warning labels—it must be fixed before the equipment is used again.

Key areas to monitor include:

- Hydraulic systems for fluid leaks or worn seals.

- Load-bearing components for cracks or weakening.

- Electrical systems for frayed wires or insulation damage.

- Tyres and wheels for visible wear or improper inflation.

Always replace damaged parts with original equipment manufacturer (OEM) components for compatibility and durability.

4. Monitor Usage and Operating Conditions

Not all EWPs work under the same conditions. Machines exposed to harsh environments or used frequently require extra attention.

For example:

- Corrosive Environments. Machines working near salt water or chemicals need regular cleaning to prevent rust.

- Rough Terrains. Road vibrations can loosen fasteners and wear out undercarriage components faster.

- Intermittent Use. EWPs that sit idle for long periods may experience hardened seals or lubrication issues.

Tailor your maintenance schedules to account for these factors. Regular operational logs can help track usage patterns and predict maintenance needs.

5. Keep Detailed Records

Having a maintenance record isn’t just ticking boxes for compliance. It helps you monitor trends, detect recurring issues, and plan what future maintenance is needed.

Your records should include:

- Inspection reports – findings and actions taken.

- Maintenance schedules and service logs.

- Repairs, replacements, and upgrades performed.

- Operator comments about machine performance.

- Photos or videos to document any damage or repairs.

Maintaining a digital logbook is a great way to make these records accessible and secure. At Altequip we have a completely paperless system whereby all service documentation is emailed directly to you. We also have a service reminder program in place. You’ll get email and SMS notifications to alert you when it’s time to book a service. Your equipment stays safe and compliant, and you don’t have the hassle of manually tracking schedules. It’s all aprt of trying to make your business more productive!

Call the Brisbane EWP Experts

Sometimes, it’s best to leave your maintenance needs in the hands of professionals. We’re a certified EWP service provider operating in Brisbane and Queensland for over a decade now. We understand the industry’s nature, but most importantly, we understand the machines themselves.

Inspections, repairs, and servicing for all types of EWPs—we have advanced tools and techniques to keep your machinery safe, efficient, and operational. With flexible service plans customised to your business needs, we make sure your machinery is always in top condition and compliant with regulations.

Contact Altequip today and a member of our friendly team will be able to answer all your questions!